製造業

単なるチョッピングボード以上のもの, それは声明です. 革新的なデザインと綿密な製造をブレンドします, すべての詳細を確保します, 材料の選択から厳格な品質チェックまで, 目の肥えたキッチンのための例外的なチョッピングボードを配達するという私たちのコミットメントを反映しています.

持続可能な & 安全な原材料保証

FSC認定パインウッドファイバー

- 持続的に調達, 責任ある林業を確保する

- より衛生的な切断面のための自然抗菌性

- ユニークで魅力的な天然木穀物を紹介します

食品グレード樹脂

- 耐久性と長寿を最大化します, 反りに抵抗します & ひび割れ

- 非多孔質を作成します, 簡単に掃除するための耐湿性表面

- 100% BPAフリー, 食品安全基準へのコンプライアンスを確保する

一部 1

CNC加工 & 初期処理

切断 & シェーピング

高度なCNCマシンを利用します, 大きなパインウッドボードは、個々のカッティングボードの形に正確に切り込まれています.

溝 & エッジワーク

CNCマシンはジュースの溝を作ります (該当する場合) デザインで指定されているように、RコーマーとRエッジでエッジを正確に仕上げます.

穴を処理します (オプション)

ハンドルホールは、特殊なCNCツールを使用して、適用可能なデザイン用に掘削されています.

一部 2

ハンドフィニッシュ & ディテール

サンディング & 研磨

各ボードは、希望の滑らかさを実現するために綿密なサンディングを受けます, その後、その自然の美しさを高め、食品に安全な表面を作り出すために磨きが続きます.

コーナーパッドのインストール (オプション)

熟練した職人がコーナーパッドをインストールします (T字型, L字型, 丸い, 等) 安全な配置を確保するために、手仕事と支援機械の組み合わせを使用する.

一部 3

クリーニング & 乾燥

クリーニング

製造プロセス中に蓄積されたほこりや破片を除去するために、細心の注意を払って洗浄されています. これにより、ブランディングとさらなる処理のための手付かずの表面が保証されます, 顧客向けのクリーンで衛生的な製品を保証する.

乾燥

切断板は、制御された空気循環システムを使用して慎重に乾燥しています, ブランディングとパッケージに移る前に、それらが完全に湿気がないことを確認する. これにより、反りが防止され、滑らかになります, 最終的なタッチの表面でさえ.

一部 4

ロゴブランディング & デザインの彫刻

レーザー彫刻またはCO2エッチング:

高精度レーザー彫刻またはCO2エッチングマシンは、耐久性のある審美的に心地よいブランディングを作成するために使用されます, ロゴ, または、カスタムデザインをまとめボードの表面に直接設計します. このプロセスは、パーソナライズされたタッチを追加するだけでなく、プロフェッショナルで永続的な仕上げを保証します.

一部 5

検査 & 品質保証

Culiexは、プロセスのすべてのステップで厳格な品質チェックを統合します. その温度を確保します, プレッシャー, 硬度, 厚さと重量は細心の注意を払って監視されます. 各カッティングボードは、海岸の硬度を達成することが確認されています 90 または上, 検査プロセス全体で、並外れた品質と耐久性を保証します.

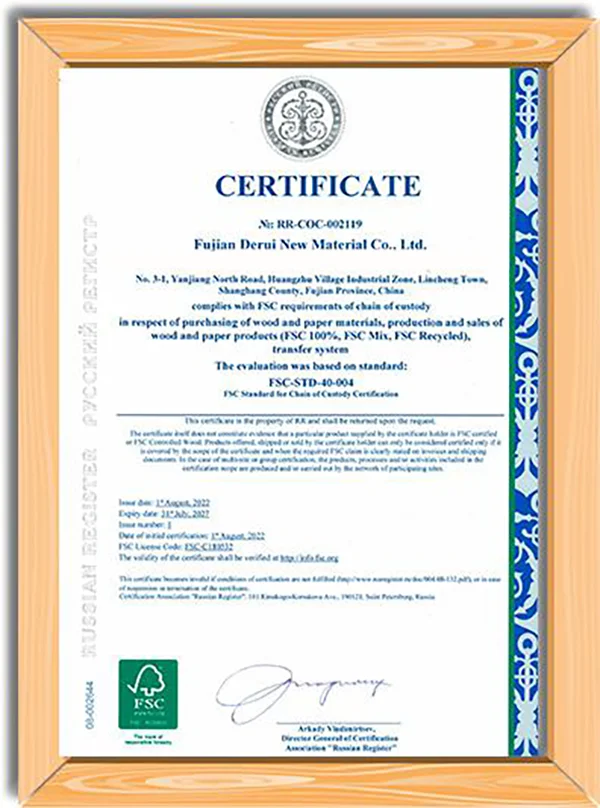

FSC

責任ある森林管理の認定

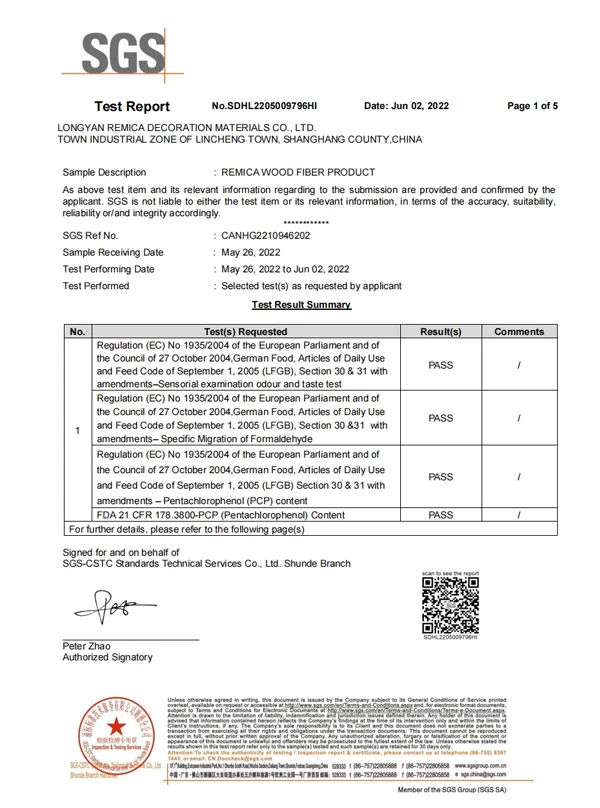

FDA

米国に会います. 食品接触安全基準

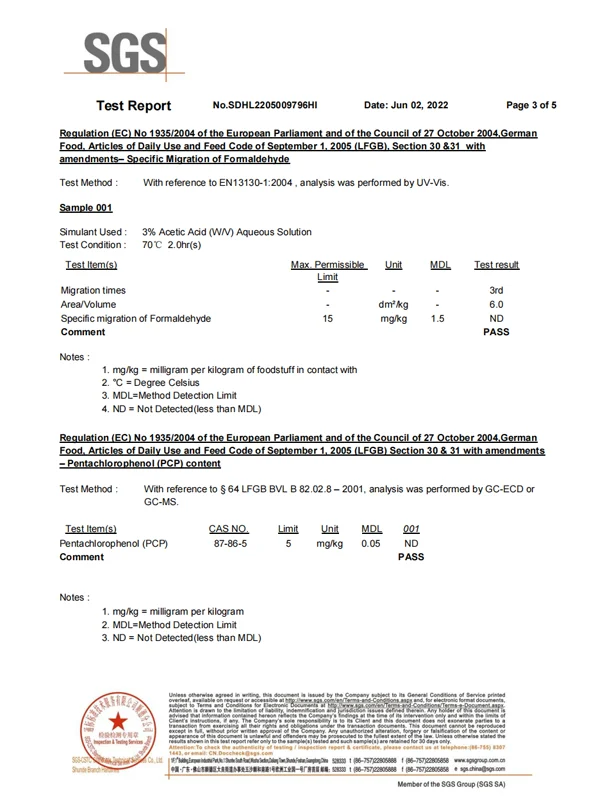

LFGB

ドイツの食品連絡先の安全基準を満たしています

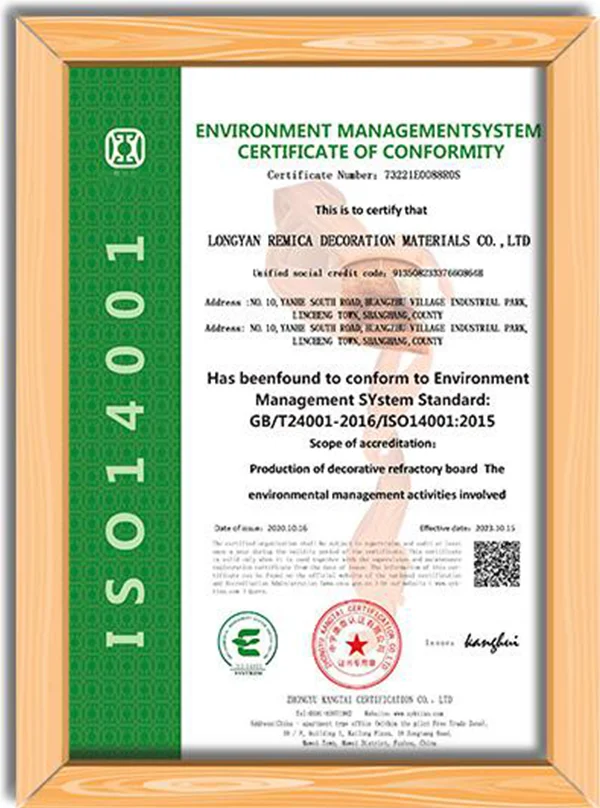

ISO 14001

環境管理システム認定

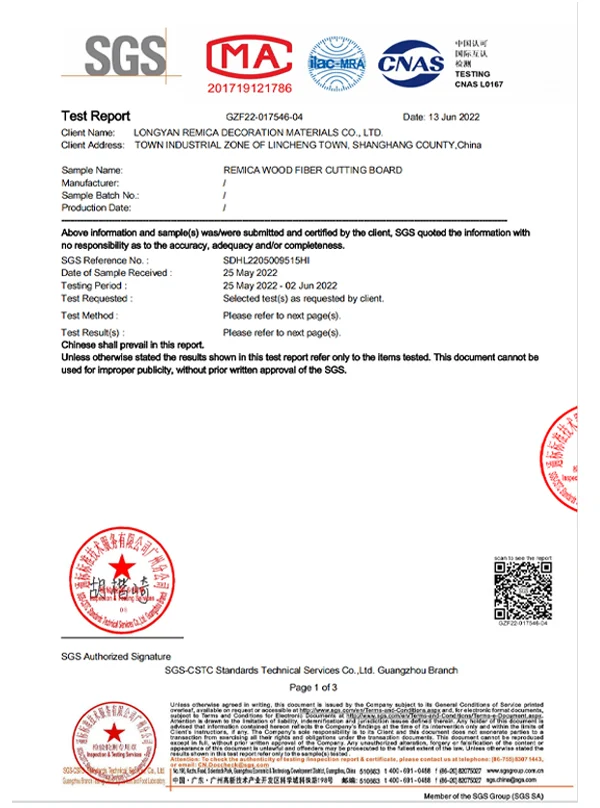

抗菌レポート

抗菌特性を示します

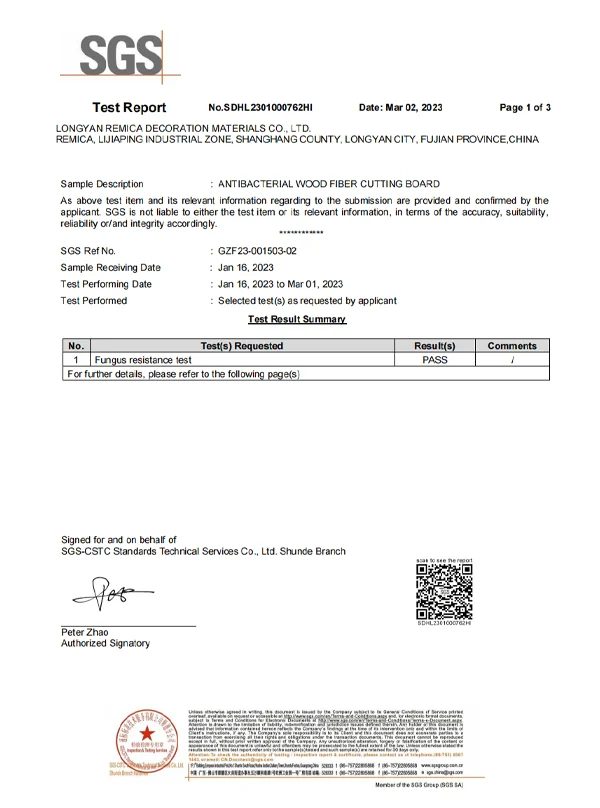

アンチモールドテストレポート

カビの成長に耐性があります, 耐久性と衛生を確保します

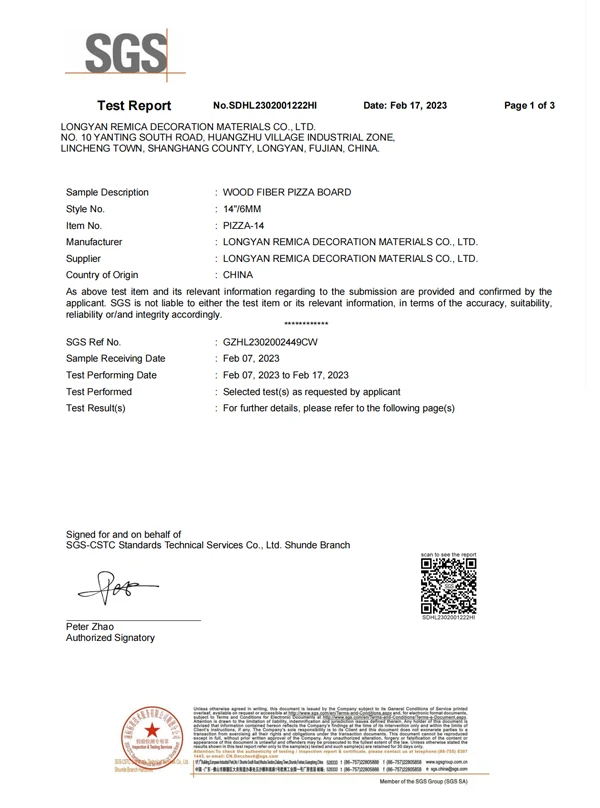

食器洗い機安全レポート

ダメージを与えることなく、食器洗い機で安全に掃除することができます

ISO 9001

品質管理システムの認定

一部 6

包装 & 出荷の準備

保護ラッピング

各ボードは、保護材料に個別に包まれています (例えば。, ラップを縮めます) 輸送中の傷や損傷を防ぐため.

ラベリング

関連情報を含む製品ラベル (例えば。, 製品コード, ケアの指示) 適用されます.

ボクシング & パレタイジング

まな板は、輸送箱に慎重に梱包されています, その後、配送センターへの効率的で安全な輸送のために、または顧客への直接的な輸送のために、パレットに積み重ねられて固定されています.