Next-Gen Kitchenware Solution

Expand and elevate your kitchenware lineup with innovative wood fiber materials. We offer low-cost development, high adaptability, and full collaboration to bring your ideas to market quickly. From concept to shelf, our engineering expertise ensures seamless execution with efficient prototyping, flexible customization, and rapid response support.

Next-Gen Kitchenware Solution That Drive Culinary Excellence

Low-Cost Rapid Development

Get custom molds without excessive upfront costs. Our efficient tooling process ensures a balance between affordability and precision.

Start small, scale smart

Minimize inventory risks of new product line for market testing while enjoying competitive pricing. Our low MOQ allows businesses to test the market with confidence.

Your brand, your rules

Customize colors, shapes, thickness & packaging in one stop. Experience complete creative control to match your brand identity.

Worry-free global sales

Simplify international distribution with our fully certified materials. We handle compliance upfront, saving you time and costs in regulatory approvals.

Sustainability Monetization

Tap into the growing demand for sustainable products. Culiex FSC-certified wood fiber materials help brands position themselves in the premium eco-friendly market.

End-to-End Partnership

Gain full transparency and responsive support. Our dedicated team provides real-time updates and 24/7 technical assistance to ensure a smooth production process.

Next-Gen Kitchenware Solution for Your Business Need

Whether you need to source bulk wholesale various kitchenware or customized designs to enhance workflow, we make it happen.

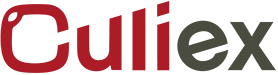

Custom Solutions Based on Kitchen Layout

Perfect for the back-of-house of large hotels, chain restaurants, and unique commercial kitchens. Tailored to fit your equipment and counter, enhances work flow efficiency, and kitchen management.

Wholesale In-Stock Kitchenware

Ideal for Restaurants, hotels, and commercial kitchenware needing immediate solutions. Quick delivery, budget-friendly for large volume, versatile for dining area presentation. Logo labeling for your business.

Case Study

Sustainable Pizza Cutter Innovation

The Challenge

A European kitchenware manufacturer sought to replace traditional plastic/nylon pizza cutters with an eco-friendly alternative. Their goals:

- Create a product using ≥80% renewable materials

- Maintain professional-grade durability for commercial kitchens

- Avoid steep price increases to ensure market competitiveness

The Solution

- Developed a wood-fiber composite pizza cutter featuring:

- Handles made from upcycled pine wood waste (FSC-certified sources) bound with food-safe resin, achieving 92% bio-based content.

- Stainless steel cutting wheel embedded during molding process

- Natural wax coating for slip resistance without chemical additives

- Pre-certified for FDA, LFGB, and NSF standards to accelerate buyer approvals

Results

Withstands 200+ dishwasher cycles vs. 50-cycle industry average for plastic handles

Diverts 8 tons/year of wood mill waste from landfills through material sourcing

Next-Gen Composite Kitchenware Solutions Culiex Offer

You Name It, Culiex Made It. From prep to display tools, Culiex offers a comprehensive range of innovative wood composite kitchenware designed to meet the unique demands of modern cooking and enhance your customers’ overall experience.